Clean shed advantages and technical parameters

-

Clean shed advantages and technical parameters

-

-

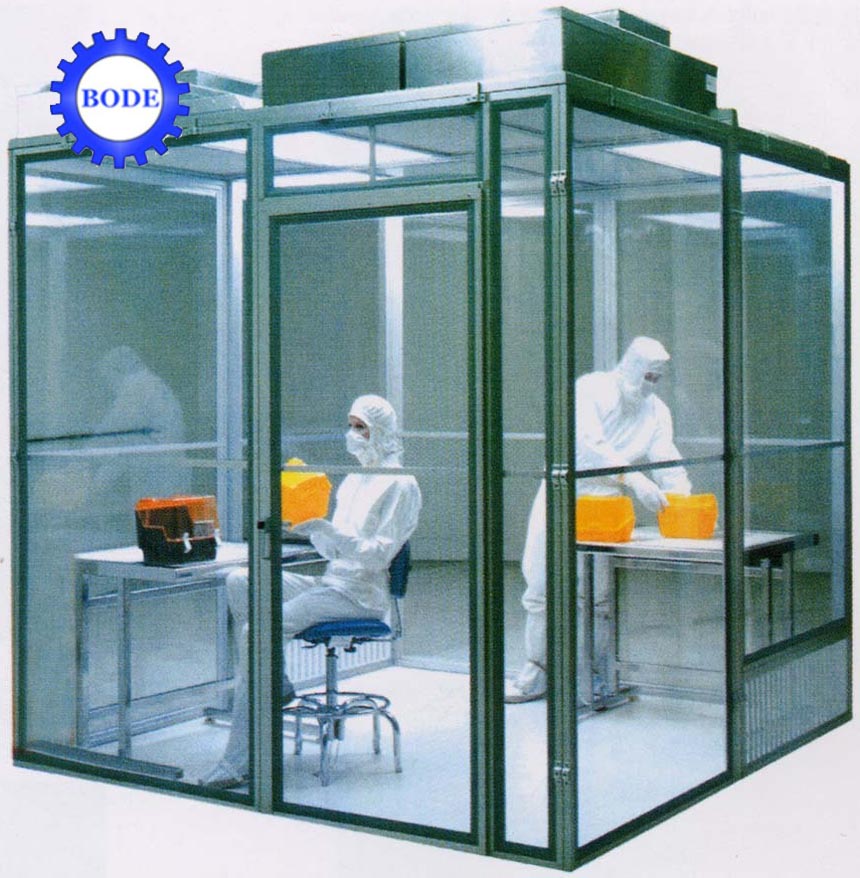

The clean shed is a simple purification device with low investment, high purification level and convenient movement. The clean layer flow cover FFU is placed on a frame assembled from a professionally cleaned aluminum profile. The top is covered by a blind plate, the tight seam is tight, the surrounding is covered with anti-static curtain/anti-static plexiglass, and the bottom part is made of positive pressure natural exhaust, which makes the cleanliness in the shed area reach 10-10000. This product is an ideal mobile device for sampling, cargo transfer, maintenance and repair of medical and health, biological products, food, electronics, hard disk and other industries.

-

-

Description of the clean shed:

-

-

1. The whole bracket is made of high-quality steel plate spray, using all kinds of materials such as stainless steel and aluminum alloy profiles. Each specific advantage can be selected according to needs.

-

-

2. The control system can take the form of centralized control or single control. Centralized control facilitates operation and management; individual control can be selected to reduce energy consumption and reduce operating costs while making rational use.

-

-

3. Adopt adjustable air volume system (both speed control and stepless speed regulation) to ensure that the wind speed in the working area is in an ideal state.

-

-

-

-

4. Applicable to ultra-clean production lines, easy to use by many people.

-

-

5. The front part of the work area adopts imported anti-static curtain, which has good transparency and is not easy to accumulate dust.

-

-

6.FFU adopts imported fan or high quality fan, which has stable performance and low noise.

-

-

7. Can be designed to be detachable for easy handling, disassembly and re-installation.

-

-

The main technical parameters:

-

-

Cleanliness level 10-300000 @≥0.5μm (US Federal Standard 209E).

-

-

The average wind speed is 0.25∽0.6m/s (the recommended wind speed is 0.3m/s).

-